About the company

PT. IKITECH Precision Grinding. was established in 2005, as a special form cutting tools manufacturing which located in Jababeka Cikarang, a well known industrial area in Indonesia. Over the years, we constantly focus in creating the most customer-centered, technologically advanced special form cutting tools industry from any type of material, either high speed steel, carbide, cermets, polycrystalline diamond, and other material. ikitech has always conducted the quality improvement in resources quality, project management, human resource and also the services.

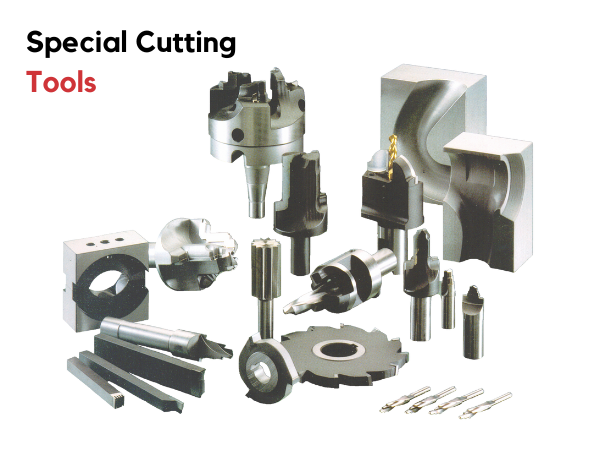

What We Do

Ikitech Precision Grinding was established to fulfill high quality special cutting tools requirement in Indonesia. We only used high quality material which processed at precision machine by experience man power. We are implementing “Build In Quality” system to assured every process had done according to in process drawing and 100% quality control checking to warranty finish good quality. Manufacturing of Special Cutting Tools, Special Drill, Special Reamer, Special Endmill, Special Holder , Special Arbor, Diamond Tool, JIG’S, CBN Tools and Other Special Tools

Our Vision

Our Mission

Provides working environments where our employees can unleash their highest potential and thrive in an atmosphere of excellency hence support our customers by superior products and unsupassed services to help them gain sustainable competitive advantage in their markets.

List of Machinery

MAZAK 51-VRX500-5X

Vertical machining center, 5 axis, with mazatrol matrix 5X control, (2) 15.7″x15.7″ sq pallet changer 20.08″ x20.08″ X,Y,Z,A axis -120/+30 degree tilt, C axis 360 degree, both @001 degree, 30 hp, 12.000Rpm, cat 40, 120 Post ATC, Rigid tapping, Tornado tapping/borring, Chip Conveyor, Collant thru, Die mold pachage, Auto tool length measuring, Mp10 work probe, Concept 2000 chip conveyor

WALTER HELI POWER

Unsurpassed surface finishes with faster grinds, Tools accuracy in the of +/-5 microns, Easy setup on the machine or an office PC so machine stays productive, Direct drives in all axis with incredible accelerationand speed (up to 2.000 IPM), Adaptive control minimizes cycled time-adjust feedrate automatically accourting to load in both gashing and fluting, New HMC 600 control faster calculation time.

ROLLMATIC 628XS

Linear glass scales for axis X, Y, Z with 0.00005mm resolution, Rotary glass scales for axis A and C with 0.00002° and 0.004° resolution, Presicion tools shank guide system and steady-rest for the tool cutting diameter, Direct drive grinding spindle temperature controlled, Patented zero run-out wheel arbor system. PerfectArbot™, 6th axis for most accurate grinding part control.

ANCA RX7

Compact manufacturing machine white strength power and versatility, it is equally efficient for single-tool as well as volume production, ideal for both manufacturing and sharpening application, double-ended spindle gives the of using up to eight grinding wheels on a single job, optimal wheel changer making 6 wheel pack available for increased versatility, 300x magnification using a camera.